Machine Shop

GK Industrial Components LLP is a leading manufacturer of high precision components suitable for Aerospace, Hydraulic, Pneumatic, food & general engineering. We are facilitated with state of the art manufacturing & measuring technology. Our Manufacturing facility includes almost all kind of CNC machines like Turning Centres, Milling Centres, Horizontal Machining Centres and Vertical Turning lathe etc.All Machines are facilitated with tool and work offset probing system and with high pressure internal coolant supply through spindle. Also, all machines are integrated with TPM Tracking, on line measuring Set & Inspection on machines and ERP.

Value Addition Equipments

To support and enhance our manufacturing efficiency we have valued added equipment like Rego-Fix (Switzerland) make powerGrip tool clamping system for better runout and rigidity of clamping tool with highest balance grades.Also, We have Haimer (Germany) make tool presetter which can preset any kind of special tool profile before it is loading to manufacturing machine. It ensures quality of components requirement and reduces scrap rate of components.

Outsource Processes

Being precision compononent manufacturer and to be specialised in machining we do outsource below listed processes from our approved sources to offer fully finished products to our valued customers.

- Forgings

- Castings

- Heat Treatment

- Surface Treatment

Product Development

We believe product development is key to accelerte business volume. Our Cross functional team of different department review components drgs.for feasibility of manufacturing and measurement at the time of RFQ. On receipt of Order confirmation from customer our team prepared timeline chart for availibility right from raw material to dispatch of product samples to customer. We make sure samples are to be submitted in line with customer requirement along with required documents within specified timeline. On approval of sampples regular production will get started and proposed delivery dates of 1st lot will be communicated to customer by our sales team in advance.

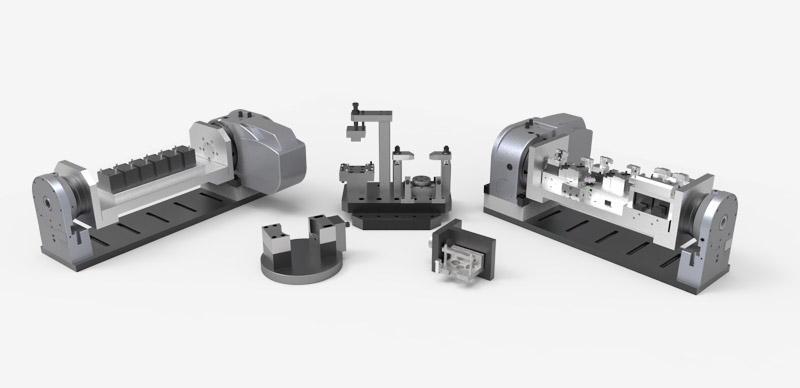

Tool Room

We have in-house facility for fixtures & some special gauges. Almost 95% of our fixtures, Zero Clamping plates, special gauges are developed in-house. Our team consist of design,Engineering, tooling and manufacturing persons review requirement of fixtures and gauges periodically. We use our measuring facility / CMM to ensures required quality standard.

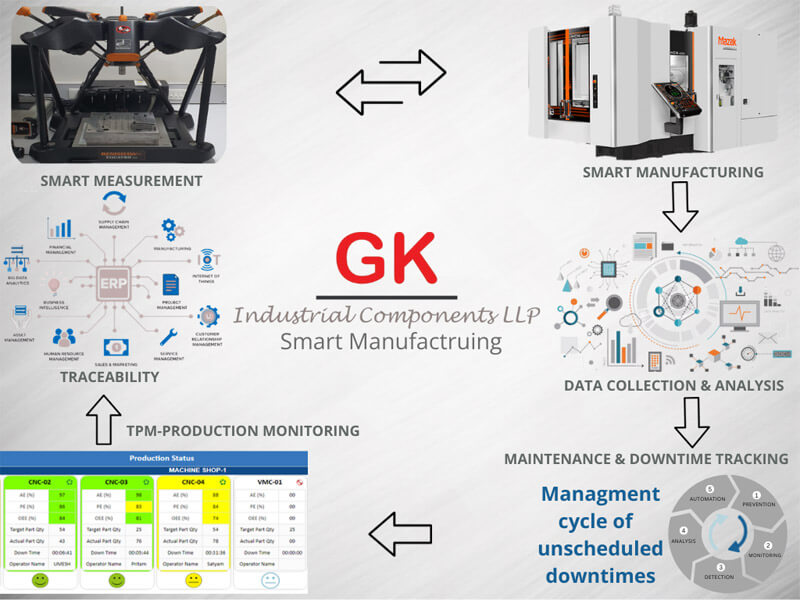

Smart Manufacturing

We have strong believe on our core values of innovation through automatio hence we believe in smart manufacturing facility. Our process analyse real time production / quality data through TPM – track which is integrated with our ERP and manufacturing processes. Integrated manufacturing & measuring set up enables us to achieve dimentional requirement including GD & T parameters of products on-line.